Top Signs Your Lift Needs Immediate Attention

June 21, 2024

How to Troubleshoot and Repair Elevator Control Panels

July 24, 2024How to Conduct a Basic Lift Maintenance Check

How to Conduct a Basic Lift Maintenance Check

How to Conduct a Basic Lift Maintenance Check? Maintaining lift (elevator) safety, reliability, and longevity is crucial for any building.

Regular maintenance not only ensures smooth operation but also helps in identifying issues early, reducing downtime, and avoiding costly repairs.

This article aims to provide a comprehensive step-by-step guide on how to conduct a basic lift maintenance check.

Preparation for Lift Maintenance

Safety Precautions

Before starting any maintenance work, it’s essential to follow safety protocols. Safety should always be the top priority to prevent accidents and ensure a secure working environment.

Begin by turning off the power to the lift to avoid any accidental movements. Use appropriate safety gear such as gloves, safety glasses, and hard hats.

Place warning signs around the work area to inform others that maintenance is in progress.

Gathering Tools and Supplies

Having the right tools and supplies is crucial for an efficient maintenance check. Essential tools include wrenches, screwdrivers, cleaning supplies, lubricants, and a flashlight.

Additionally, a maintenance checklist is vital to ensure that no steps are overlooked during the process. This checklist should cover all aspects of the lift system, from the cabin to the machine room.

Inspecting the Lift Cabin

Cabin Interior Check

The lift cabin is the most visible part of the system and should be inspected for cleanliness and wear. Check for any signs of damage to the walls, floors, and ceiling.

Ensure that the cabin lighting is functional and that mirrors, if any, are intact and clean. A clean and well-maintained cabin enhances the user experience and reflects positively on the overall building maintenance.

Door Operation

Smooth door operation is critical for safety and convenience. Observe the doors as they open and close, noting the speed and any unusual noises.

Ensure that the sensors are functioning correctly to prevent the doors from closing on passengers. Properly functioning doors are essential to prevent accidents and ensure a seamless operation.

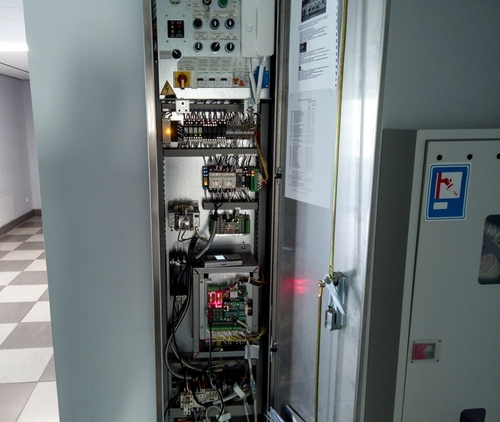

Control Panel and Buttons

The control panel and buttons should be inspected for functionality. Press each button to ensure it responds correctly and verify that the indicator lights are working.

Check the panel for any signs of damage or wear. A well-functioning control panel is crucial for the efficient and safe operation of the lift.

Checking the Lift Shaft

Shaft Cleanliness

A clean lift shaft is essential for safety and smooth operation. Inspect the shaft for debris, dust, and signs of wear or damage on the walls.

Regular cleaning of the shaft helps in preventing the accumulation of dirt that could interfere with the lift’s operation.

Guide Rails

Guide rails play a significant role in ensuring smooth and stable lift movement. Check for alignment issues and look for signs of wear or damage.

Ensure that the rails are clean and well-lubricated. Properly maintained guide rails are crucial for the lift’s stability and safety.

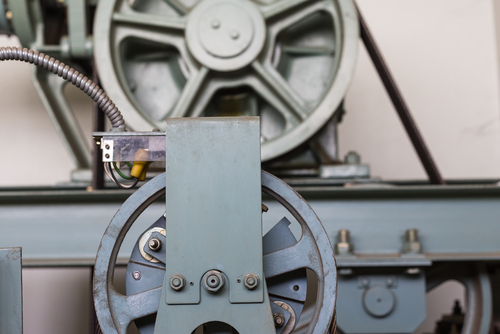

Cables and Pulleys

Cables and pulleys are vital components that need regular inspection for signs of wear and tear. Look for frayed or damaged cables and ensure that pulleys rotate smoothly.

Verify that the cables have the proper tension. Regular inspection and maintenance of cables and pulleys are essential to prevent accidents and ensure safe operation.

Examining the Lift Machine Room

Motor and Gearbox

The motor and gearbox are critical components that should be inspected for proper operation.

Listen for unusual noises that could indicate a problem, and look for signs of overheating or leaks.

Ensure that all moving parts are properly lubricated. A well-maintained motor and gearbox are essential for the lift’s efficiency and reliability.

Control System

The control system should be inspected for any signs of malfunction. Verify the condition of the control panels and ensure all connections are secure.

Look for any error codes or warning lights that could indicate a problem. A properly functioning control system is crucial for the safe and efficient operation of the lift.

Braking System

The braking system is vital for lift safety and must be checked regularly. Inspect the brake pads for wear and ensure the emergency brakes operate correctly.

Test the braking system under different conditions to ensure it functions properly. A reliable braking system is essential for the safety of lift passengers.

Lubrication and Cleaning

Lubricating Moving Parts

Regular lubrication reduces friction and wear on moving parts, prolonging their lifespan. Identify the parts that need lubrication, use the appropriate type of lubricant, and apply it correctly. Proper lubrication is essential for maintaining the smooth operation of the lift.

Cleaning Components

Cleaning various lift components helps maintain their performance and longevity. Use appropriate cleaning agents and avoid harsh chemicals that could damage the components.

Ensure all parts are dry before reassembly. Regular cleaning prevents the buildup of dirt and grime that could interfere with the lift’s operation.

Testing Lift Operation

Running the Lift

After completing the maintenance checks, it’s important to test the lift’s operation. Run the lift through its full range of motion, testing different floors and speeds.

Observe for any unusual behavior or noises. Testing the lift ensures that all components are functioning correctly and that the maintenance was successful.

Emergency Systems Check

Emergency systems are crucial for passenger safety and must be tested regularly. Test the emergency stop buttons, verify the operation of alarm systems, and ensure communication devices work properly.

Regular testing of emergency systems is essential for ensuring passenger safety in case of an emergency.

Documenting and Reporting

Maintenance Log

Maintaining a detailed log of all maintenance activities is important for tracking the lift’s condition and performance.

Record the date and time of checks, note any issues found and actions taken, and track regular maintenance schedules.

A maintenance log helps in identifying recurring problems and planning future maintenance activities.

Reporting Issues

Any significant issues found during the maintenance check should be reported to a professional technician.

Describe the issue clearly, include any relevant details, and schedule professional inspections or repairs as needed. Prompt reporting and repair of issues are essential for maintaining the lift’s safety and reliability.

Scheduling Regular Maintenance

Establishing a Routine

Establishing a regular maintenance routine is crucial for the ongoing safety and efficiency of the lift.

Set a schedule based on manufacturer recommendations, usage frequency, and the building’s needs. Regular maintenance helps in identifying and addressing issues before they become major problems.

Professional Inspections

In addition to basic maintenance checks, regular professional inspections are important. Professional services can identify and address issues that may not be apparent during basic checks.

Professional inspections complement routine maintenance and ensure comprehensive lift safety and reliability.

Ensuring Compliance with Safety Standards

Compliance with local safety regulations and standards is essential for lift operation.

Stay informed about regulations, incorporate safety standards into maintenance routines, and work with certified professionals. Adhering to safety regulations ensures the lift operates legally and safely.

Regularly updating safety protocols to reflect new standards and practices is crucial.

Review safety standards periodically, incorporate feedback from inspections, and ensure all staff are trained on updated protocols. Keeping safety protocols up-to-date helps in maintaining a safe and compliant lift system.

How to Conduct a Basic Lift Maintenance Check – Conclusion

Conducting a basic lift maintenance check involves several important steps: preparation, inspecting the lift cabin and shaft, examining the machine room, lubrication and cleaning, testing operation, documenting and reporting, scheduling regular maintenance, and ensuring compliance with safety standards.

Implementing these practices ensures that lifts remain safe, reliable, and efficient.

Regular maintenance not only improves safety and reduces downtime but also extends the lifespan of lift components, providing long-term benefits for building operations. Get started today!

Are you seeking professional and reliable lift maintenance services in Singapore? Contact us today!