How Long Should Elevator Last?

January 17, 2021

Is Installing Elevator At Home A Good Choice?

March 16, 20215 Common Reasons for Lift Breakdown

5 Common Reasons for Lift Breakdown – A lift breakdown can happen due to many factors. Sometimes, a power failure can be the culprit. Poor maintenance can also cause lift breakdown.

The condition is irritating since we cannot get any help until a professional fixes the issue. However, you can prevent a lift breakdown with regular lift maintenance. Regular inspections can enable you to fix the issue fast and avoid any major replacement costs.

Whenever you notice any problem, take the help of experts to prevent further deterioration. Also, a properly functioning lift can minimize energy consumption by up to fifteen percent.

Let’s cover the five common reasons for a lift breakdown. We will also know how to avoid such conditions.

1. Power Failure

Power failure is a common problem. Many of us might have encountered this problem more than once. A power failure can be scary especially when you are in the lift. A power failure can lead to a time-consuming process.

Your lift needs a significant amount of energy for operating. It can impact the utility system of the building and lead to a power failure. The most affected part might be your motor. When your motor will not be working, you will have to either purchase a new motor or repair the existing one.

Both will demand time and effort. If you experience power failure more often, you can consider conducting a power quality survey. During the process, the technician will be able to find out the cause and fix the issue.

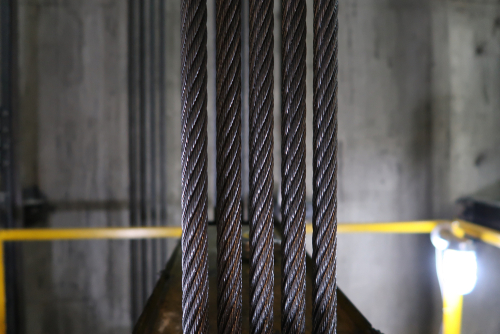

2. Damaged Sheaves

Worn sheaves might be the result of excess wear and tear. The sheave is an important component that ensures the smooth functioning of a lift. However, the integrity and functionality of the sheaves might be affected over time.

If you want to prevent a lift breakdown, you will have to inspect your sheaves. Whenever you notice any sign of damage, you can consider repairing it. As mentioned above, an early repair will prevent further damage.

You can take the help of professionals to ensure that the sheave is in good condition. They are thoroughly experienced. They can bring back the functionality by regrooving your lift. However, when the condition is beyond repair, you might need to spend on the sheave replacement.

3. Poor Lubrication

Most machines cannot work their best without proper lubrication. Similarly, the components of your lift need to be lubricated to ensure smooth functioning. You can use clean oil for lubrication. However, tiny metallic particles can break from your lift after long use.

These particles might impact the lubrication process. The tiny particles might affect the efficiency and performance of your lift. You can notice a foul-smelling odor or some other issues. You can prevent this condition by doing an oil analysis.

The oil analysis test will check the oils to find out the impurity level. They can help you to choose the right oil to lubricate your lift and prevent any contamination.

4. Bearing Malfunction

Poorly functioning bearings can be another cause of a lift breakdown. You can hear unusual noises or other disturbances due to malfunction. You should never avoid these kinds of issues. The noise might come from a minor issue.

However, if you leave it untreated for a long, the problem will be more. As a result, you might need to spend much more on the replacement. When malfunctioning bearings will be damaged, your lift will not work anymore.

You can fix the bearing problem on your own. Also, you can take the help of experts.

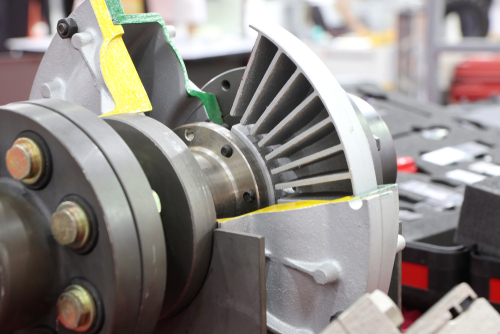

5. Misaligned Motor Drive

You might experience a lift breakdown due to a misaligned motor drive. It can cause a lot of problems. The shaft alignment plays a key role to offer smooth functioning. Even if the alignment is a bit off, the bearings will be affected.

They will wear fast while causing many different problems. You can repair the condition. It is better to take the help professionals since they can find out the issue and fix it correctly to prevent further damage.

They can use laser technology to get a better view of the alignment. They can even find out minor damages and fix them.

5 Common Reasons for Lift Breakdown – Conclusion

You can prevent a lift breakdown with regular inspection. Some breakdowns are unexpected. You cannot prevent them without predicting the problem. But, regular maintenance and inspection can minimize the possibility to a great extent. Whenever you have doubt, talk to an expert straight away.