How Do You Do Lift Maintenance?

July 14, 2021

Landed property Lift Maintenance in Singapore

September 2, 2021Lift Maintenance Checklist in Singapore

Lift Maintenance Checklist in Singapore Elevators might seem like simple pieces of machinery, but they’re quite complicated and can sometimes require maintenance works on a consistent basis. This helps in the main purpose of its smooth and error-free operation. With elevator malfunctions, you can bear safety hazards and would eventually need to spend for costly repairs.

Thus, it’s best to avoid such problems beforehand and ensure that all equipment is working in perfect condition and complies with all Singapore building laws. Time to time maintenance and inspections mitigates such risks.

Have you ever considered what the elevator repair professionals in Singapore do while servicing elevators? Let’s have an insider look at the steps that a lot of elevator companies use in the inspections in Singapore.

The following lift maintenance checklist ensures that elevator maintenance and inspections are correctly performed:

Time to time lift maintenance

Approach with a planned elevator maintenance mindset and have a preventive procedure. Bear in mind that faulty elevators can disrupt normal operations and result in user inconvenience. Maintenance also ensures that the elevator operates perfectly.

Locate the elevator safety test form for the elevator

Separate the “often” which is confused with elevator inspection. Having an elevator safety test should be the topmost priority. The elevator maintenance provider must perform a safety test of Category 1, 2, 3, or 4 and complete the necessary documentation. All local codes work with different requirements for safety testing. As the building owner, it is necessary to ensure that you’ve got current test documents and these are available for review.

Check for proper fire extinguisher

All machine rooms of elevators require fire extinguishers that have been properly maintained and tested according to the ASME A17.1 to 8.6.1.6.5. Ensure that you’re familiar with the testing requirements of fire extinguishers and ensure that they’ve got the latest tags. It is recommended to mount the extinguisher near the machine room jamb side entrance door instead of the worker’s path for a quick exit.

Check whether all Emergency Contact Phones are Properly Working

24-hour two-way voice communication for dispatching emergency help should be available as per the ASME A17.1 – 2.27.1.1.3. Ensure that you’ve tested all phones before the arrival of the inspector. When the phones don’t properly work, you must check whether the phone is defective or the phone lines are having issues.

Elevate the audits, inspections, checklists, and much more with mobile forms solution. With Dynamic digital forms, the elevator inspection team can directly send reports to back-office systems.

Also, make sure to provide updates for monthly fire service tests. The elevator has been designed with a certain firefighter’s mode to have control of the emergency situation. The mode is known as Phase 1 and Phase 2 service of firefighters and they have to be logged monthly and tested according to the ASME A17.1 to 2.27.3. Many maintenance contracts for elevators don’t include monthly tests. As an owner, you should record and test the outcomes by yourself. Ensure that the log gets updated timely.

Identify the problem spots

Knowing that the elevator helps in anticipating the issues, you must fix them immediately. Around 70% of elevator maintenance calls are done because of malfunctioning unit doors therefore closed-loop door operators that keep an eye on the door opening speed and can be a good solution for sorting the problem.

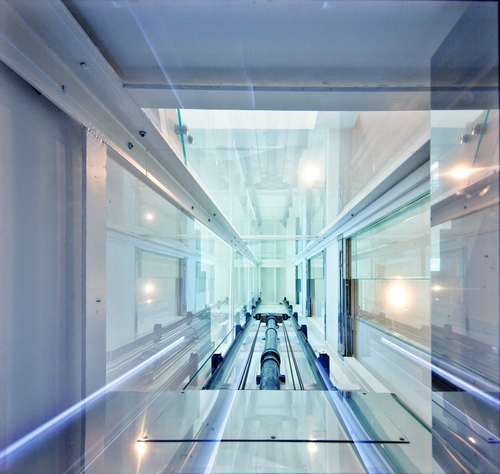

Ensure that the machine room has no problem

Not only do elevators need to work in perfect condition as the machine rooms should also be looked after. The elevator machine room has to be self-closing and without authorization, no one should have access. The room must get adequate lighting and should be free of fire hazards.

All Elevator Units Must be in Top Working Order

Lift maintenance checklist must reveal either of the following problems: dirtiness, broken lights, elevator pit also has water debris, improper door functioning, malfunctioning fire recall service, non-working emergency lights, cable measurements not complying with the present regulations, and much more.

Things to include in Checklist for Elevator Maintenance

Before inspecting the elevators, you can make a checklist for elevator maintenance for ensuring that risks are at a minimum. This keeps the elevators running smoothly and efficiently. The checklist has relevant elements to look at while inspecting the elevators:

Inside Car

- Ensure that the doors easily open and close without facing any obstructions

- Also, look for any damage signs on the handrails, walls and ceilings

- Replace burned-out lights

- Check out for any emergency phones

Outside Car

- Replace lights that burned on each floor

- Check for clearances and door panels

- Thoroughly test fire alarm systems and smoke detector

- Check on oil level while ensuring that all systems get efficiently lubricated

In the Cabin Top

- Clear all accumulated debris on the cabin top

- Examine lift shaft to get any vandalism evidence and pests or rodents

- Inspect stop switch and inspection station of the cabin top

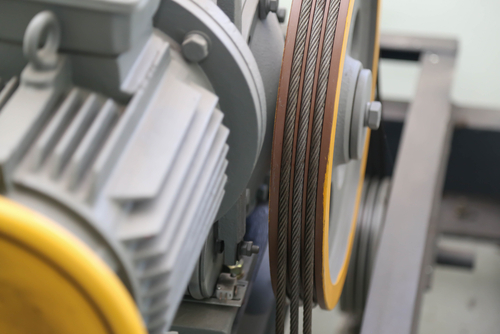

- Check the cabling for any wear and tear, while carefully examining all connections

- Inspect door operator with all connected components

- Check rollers, leveling devices, and guide rails

- Any unwanted debris which can become a safety hazard is cleared by tower lift engineers. They also ensure that the lift has clean working components are lubricated and are free of any dirt

Lift Maintenance of Machine Room

- You must ensure that the machine room remains clear of any unsuitable material

- Check for oil level

- Inspect all the components to look for any wear evidence, leakage, and unexpected vibration

- Carry out the component lubrication where it seems necessary

Pit Lift Maintenance

- Check to ensure proper working of stop switch, lights, and GFI outlet

- Examine the condition of rollers, switches, and guided rails

- Check operation of sump pump and also clean it

- Inspect that the spring buffers have been attached securely. Check for the signs of corrosion and its proper alignment

- With a faulty lift, you can create financial troubles for the business – especially when you require emergency repairs. Lifts that don’t get timely servicing become a safety hazard for the passengers

Lift Maintenance Checklist in Singapore – Conclusion

With the right lift maintenance checklist in Singapore you can easily lessen risks, avoid costly repairs while ensuring that the elevator works according to the regulations and pertinent codes. With successful inspection, you’ll get issued with a certificate that is possible to display in the elevator. Also, maintenance reports must have monthly maintenance summaries and requesting reporting.