Lift Maintenance in Commercial Properties

September 27, 2023

Reducing Lift Downtime: Keeping Lifts Operational for as Long as Possible

November 1, 2023The Lifespan of Elevator Components: When to Replace

The Lifespan of Elevator Components When to Replace

The Lifespan of Elevator Components: When to Replace. Elevators are pivotal in modern buildings, shaping our urban landscapes and enabling efficient vertical transportation.

However, behind the scenes, a complex interplay of elevator components ensures these vital machines’ safe and reliable operation.

This article delves into the world of elevator components, exploring their significance, lifespan, maintenance, and replacement.

Elevators have become an integral part of urban life, revolutionizing how we access tall buildings and providing essential mobility for people of all ages and abilities.

These mechanical marvels have made skyscrapers not just possible but practical, transforming how we live and work.

The Role of Elevators in Our Lives

Elevators have revolutionized urban life, making towering skyscrapers accessible and transforming how we live and work.

They are more than mere convenience; they are essential to the modern urban fabric. The comfort and efficiency they offer have reshaped the world’s cities.

Elevators have transcended their status as mere utility features to become iconic symbols of progress and technological advancement.

Whether in gleaming corporate skyscrapers or cozy residential buildings, elevators profoundly impact our daily lives.

Elevator Components

Elevator systems are intricate assemblies of various components, each with a specific role in ensuring smooth operation.

Understanding these components is key to comprehending the challenges of maintenance and replacement. Major elevator components include:

- Hoisting Machines and Motors: Responsible for vertical movement.

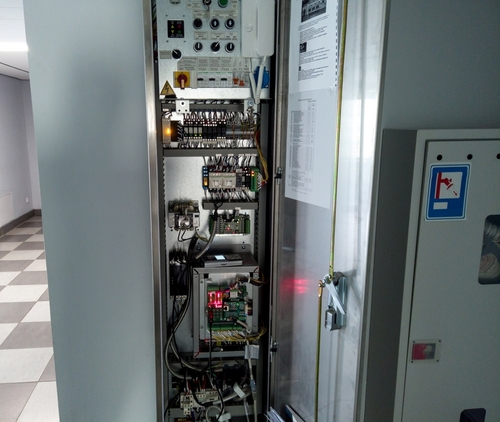

- Control Panels and Electronics: The brains behind elevator operation.

- Doors and Door Operators: Ensuring safe entry and exit.

- Cables and Suspension Systems: Providing structural support.

Each of these components contributes to the elevator’s overall function, and their proper maintenance and replacement are essential for passenger safety and operational efficiency.

Factors Affecting the Lifespan of Elevator Components

Several factors influence the lifespan of elevator components. Environmental conditions, frequency of use, and technological advancements all play crucial roles.

In Singapore’s unique climate, humidity and temperature can significantly impact.

In the tropical climate of Singapore, elevators are subjected to higher humidity levels and elevated temperatures, which can accelerate wear and tear.

Additionally, elevators in high-rise buildings experience more frequent use, leading to more significant stress on their components.

Routine Maintenance: Extending Component Lifespan

Regular maintenance is the lifeline of elevators. Proper servicing, inspections, and adherence to best practices are essential for preserving the integrity of elevator components.

In Singapore, where elevators are ubiquitous, the importance of quality maintenance cannot be overstated.

The importance of routine maintenance cannot be overstated. Elevator components undergo significant stress and wear during their operation.

Regular maintenance helps identify issues early, preventing costly breakdowns and ensuring passenger safety.

Signs of Wear and Tear

Recognizing the telltale signs of wear and tear is crucial for proactive maintenance. From unusual noises to sluggish performance, identifying these issues early can prevent costly breakdowns and ensure passenger safety.

Unusual noises, such as grinding, squeaking, or clunking, can indicate various components’ problems.

Additionally, if elevator doors open and close slowly or erratically, it could be a sign of worn door operators or control panel issues.

Sluggish or delayed response to floor selections indicates that maintenance or component replacement may be necessary.

Lifespan of Different Elevator Components

Elevator Cables

Elevator cables are the unsung heroes that bear the weight of elevator cars. Understanding their lifespan and maintenance requirements is vital.

Replacement should be considered when wear, corrosion, or fraying are observed.

Elevator cables are subjected to immense stress and must be regularly inspected for signs of wear and tear.

If cables show signs of damage, such as fraying, corrosion, or kinking, they should be replaced promptly.

Additionally, modernization projects may include upgrading to stronger and more durable cable materials to enhance safety and longevity.

Elevator Motors

Elevator motors come in various types, each with its expected lifespan. Signs of motor wear, such as overheating or increased energy consumption, should prompt replacement considerations.

Elevator motors are the workhorses of the system, responsible for moving the elevator car and its passengers.

Over time, these motors can experience wear and tear, leading to decreased efficiency and reliability. Signs that a motor may need replacement include overheating, increased energy consumption, or erratic performance.

Control Panels and Electronics

Control panels and electronic components are the nerve center of elevators. Their lifespan depends on several factors, including environmental conditions and maintenance practices.

Regular inspections and prompt replacement of faulty components are essential.

Control panels and electronic components are critical in elevator operation, ensuring smooth and safe transitions between floors.

To extend their lifespan, it’s important to keep them clean and free from dust and debris, which can affect their performance.

Additionally, regular inspections by qualified technicians can help identify potential issues and prevent system failures.

Safety Features

Safety features are non-negotiable in elevators. Their lifespan should align with regulatory requirements.

Frequent inspections and immediate replacement of malfunctioning safety features are paramount for passenger safety.

Safety features, such as emergency brakes, door sensors, and overload detectors, are essential for ensuring passenger safety in elevators.

These features undergo rigorous testing and must adhere to strict safety standards. Regular inspections and prompt replacement of malfunctioning safety features are essential to maintaining a safe and reliable elevator system.

Hiring a Professional Elevator Maintenance Service

Outsourcing elevator maintenance and component replacement to professionals is a wise choice.

Choosing a reputable elevator maintenance service provider in Singapore requires careful consideration of their track record, certifications, and adherence to safety standards.

When it comes to elevator maintenance and component replacement, it’s crucial to entrust the job to qualified professionals.

Elevators are complex systems that require specialized knowledge and expertise to maintain and repair.

Hiring a reputable elevator maintenance service provider in Singapore ensures that your elevators are serviced by certified technicians who follow industry best practices and safety standards.

Frequently Asked Questions (FAQs)

What is the typical lifespan of elevator components?

Elevator component lifespans vary based on usage, maintenance, and environmental factors. Generally, motors may last 15-20 years, while cables can endure 20-25 years with proper care.

It depends on several factors, including the component type, maintenance frequency, and environmental conditions.

However, as a general guideline, elevator motors typically have a 15 to 20-year lifespan, while elevator cables can last anywhere from 20 to 25 years with proper care and maintenance.

Can elevator components be replaced individually, or is it better to replace the entire system?

Individual component replacement is common and cost-effective if identified early. However, modernization or system replacement may be more economical and efficient in some cases.

Elevator components can often be replaced individually, which can be cost-effective, especially when addressing specific issues or wear and tear in one component.

However, in cases where multiple components are reaching the end of their lifespan or when a comprehensive modernization is desired, replacing the entire elevator system may be more efficient.

This decision should be based on a thorough evaluation by qualified elevator technicians.

Are there any warning signs that indicate the need for immediate elevator component replacement?

Yes, warning signs include unusual noises, sluggish performance, frequent breakdowns, or failure to meet safety standards. Prompt action can prevent accidents.

Several warning signs may indicate the need for immediate elevator component replacement. These include:

- Unusual Noises: If you hear grinding, squeaking, clunking, or other unusual sounds when the elevator operates, it may indicate a problem with one or more components.

- Sluggish Performance: If the elevator doors open and close slowly, or if the elevator car moves slowly between floors, it may be a sign of component wear or malfunction.

- Frequent Breakdowns: If the elevator experiences frequent breakdowns or requires frequent service calls, it clearly indicates that components may be nearing the end of their lifespan.

- Failure to Meet Safety Standards: If safety features, such as emergency brakes or door sensors, fail to function correctly or do not meet safety standards during inspections, immediate action is required to ensure passenger safety.

When any warning signs are observed, it’s essential to take prompt action to assess and address the issue. Delaying necessary component replacement can lead to safety risks and more extensive and costly repairs.

How often should elevators in commercial buildings be inspected and serviced?

Commercial elevators should undergo regular inspections and servicing at least once a month, with more comprehensive examinations annually. However, usage patterns and regulations may require more frequent checks.

In commercial buildings with high elevator usage, it’s crucial to adhere to a strict inspection and maintenance schedule to ensure passenger safety and the uninterrupted operation of elevators.

Typically, commercial elevators should undergo monthly inspections and routine servicing. In addition to these monthly checks, more comprehensive annual examinations are essential to identify and address any potential issues or component wear.

However, it’s important to note that specific regulations and usage patterns may dictate more frequent inspections.

Bus commercial property elevators may require frequent servicing to maintain safety and reliability.

The Lifespan of Elevator Components: When to Replace – Conclusion

Understanding the lifespan of elevator components and when to replace them is essential for ensuring passenger safety and the reliable operation of these crucial machines.

Elevators are more than just transportation devices; they are the lifeblood of modern urban living.

Proactive maintenance and compliance with regulations are paramount for a safe and efficient elevator system.

By following best practices and seeking professional assistance when needed, we can continue to benefit from the convenience and efficiency that elevators bring to our lives.

In summary, the lifespan of elevator components should never be underestimated, and their replacement should always prioritize safety and functionality.

Whether in the bustling commercial heart of Singapore or the tranquil corridors of residential buildings, elevators remain a vital part of our daily lives, and their proper maintenance ensures a smooth and secure journey for all passengers.

Are you seeking professional and reliable lift maintenance services in Singapore? Contact us today!