When To Call A Lift Repair Company?

November 24, 2021

How Often Should I Service My Home Lift?

February 8, 2022How To Increase Lifespan Of My Lift?

How To Increase Lifespan Of My Lift? The lifespan of the lift is a very important thing. It tells you how long your lift will last and it provides a guideline for the service life of the components in your lift. The main factors that have the biggest impact on the lifespan of a lift include Lift Type, Lift Configuration, Surface type, and Design.

By choosing the right lift for your application it will increase the life of your lift tremendously. Here are 10 tips to help you choose the right lift and increase your lift’s lifespan.

1. Avoid Frequent Start-Up And Shutdown Cycles

Repeated start-ups and shutdowns will reduce the lifespan of your lift. For example, This is an important consideration for lifts mounted indoors or through floors that don’t offer easy access for regular inspections. It may be necessary to shut down the equipment to conduct safety checks or do maintenance, but if possible try to do it less frequently.

The frequency of start-ups is influenced by the lift’s duty cycle. A duty cycle is defined as the ratio of the time during which a piece of equipment is in operation divided by the total time over a certain period. Lifts that are intended for heavy and continuous use, such as those mounted on trucks or trains, will be required to operate with a high duty cycle.

2. Follow The Manufacturer’s Recommended Maintenance Schedule

To prevent unexpected lift repair costs, follow the advice of your lift’s manufacturer about how often maintenance should be performed. When you set up a routine for this type of preventative maintenance, it can prolong the life of your equipment by keeping it in good shape and avoiding expensive breakdowns.

By following the manufacturer’s service schedule, you can avoid problems caused by lack of lubrication or wear from dirt and dust.

3. Keep It Clean

It is a good idea to regularly clean your lift for a variety of reasons. Keeping the lift free of dirt and grime will improve performance and extend lifespan. Also, keeping it clean allows for better inspection of the equipment’s components.

Dirt and dust can wear down a lift, so if your lift is exposed to dusty or dirty working environments it will likely have a shorter lifespan than one that isn’t. By taking care of your lift and keeping it clean, you can avoid common problems associated with a dirty environment.

4. Inspect Your Lift Often

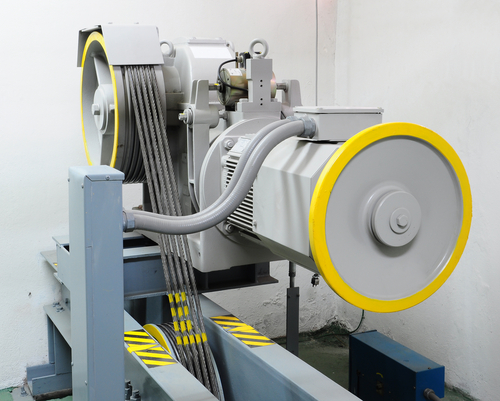

Regular inspection is another important practice to increase the lifespan of your lift. Check bolts regularly for tightness and check for signs of wear when inspecting pulleys, chains, ropes, bearings, and other moving parts.

By identifying potential problems before they become serious, you will be able to catch small issues before they become big repairs or costly breakdowns. Also, by inspecting your lift more frequently, you can catch potential safety hazards before they become a problem.

5. Don’t Let Lift Components Overheat

When components of a lift overheat, the life of the component is shortened dramatically and it becomes less durable. For example, if pulleys or chain falls are overloaded then they may overheat and their life span will be shortened. To avoid overheating your lift components, you must maintain the pulleys and chains properly.

Also, proper maintenance of other lift parts can help reduce overheating. This includes bearings, sheaves, and ropes.

6. Avoid Frequently Reversing Direction

Reverse direction if possible. For example, If your lift must move loads in both directions, avoid reversing the load frequently since this puts an increased strain on components of your lift. Also, try to limit the number of times you reverse the direction by planning your lift layout carefully. This will allow for load movement in one direction and may help extend the life of your lift.

7. Avoid Overloading

Overloading a lift can significantly reduce its lifespan. For example, If your inflatable lift is designed to lift only 10 tons, then don’t exceed that weight capacity to maintain a long lifecycle for the equipment. Also, avoid overloading the load capacity of the equipment when employing it in transport applications. This can cause problems with stability that may be dangerous.

8. Avoid Excessive Vibration

Vibrations can shorten the lifespan of many components of your lift, particularly bearings, bushings, and mechanical linkages. When installing your equipment for operation or storage, make sure it is in a stable location that will reduce vibrations to prolong the life of your lift components.

Also, in a transport application, a stable attachment system will help reduce vibrations and extend the life of your lift. You can do this by minimizing movement within the attachment system.

9. Avoid Over-Tightening or Under-Tightening Screws/Bolts

Keeping screws, bolts and other fasteners tight can prevent loosening from vibration and fatigue which can reduce the lifespan of your lift components. However, overtightening a screw or bolt can also damage the threads on components of your lift and cause premature failure. A good rule of thumb is to tighten all fasteners until they start turning hard.

This means they have reached their limit and will not serve well if tightened further.

10. Avoid Extreme Temperatures

Extremes in temperature will affect the lifespan of lift components. For example, if your lift is stored or installed in an area with large temperature differences, then the parts inside the equipment may expand and contract at different rates which can cause damage to components. If possible, store your inflatable lift out of direct sunlight.

Also, try to keep your lift away from areas that will be exposed to environmental extremes. These areas may include the roof of a parking garage and an open deck/porch.

How To Increase Lifespan Of My Lift? – Conclusion

Maintaining your lift regularly through proper inspections will help to ensure a longer lifespan for the equipment. By following these 10 tips, you can avoid common problems that may shorten the life of your lift.

Also, by being proactive in maintaining your lift, you can catch potential safety hazards before they become a problem. Your lift should operate properly and provide a safe work environment for everyone. The last thing you want is to risk injury or even death at your job site due to faulty equipment.